The Missing Link in Battery Testing

Feb 2, 2026

The battery testing industry has undergone a remarkable transformation over the past decade. Cloud-based analytics platforms have revolutionized how we process, interpret, and analyze cycler data. Companies like Voltaiq and Micantis enable teams to visualize gigabytes of test data, run ML models, and extract insights that would have been impossible just years ago. The data science side of battery R&D has finally caught up to other advanced industries.

Yet there's a glaring gap in this modernization story -- protocol design and execution remains stuck in the past.

The Hidden Bottleneck in Your Testing Pipeline

Great battery data doesn't start when you analyze results—it starts when you build the test protocol. A perfectly executed HPPC test with a C-rate typo produces perfectly useless data and causes irreversible cell damage. An RPT sequence with a logic error might run for weeks before anyone notices the problem.

The quality of your testing output is fundamentally constrained by the quality of your protocol inputs and design.

Today's reality looks like this: A test specification arrives—maybe an internal GITT procedure, maybe customer requirements for cycle-life testing. One or two "cycler experts" who understand the vendor-specific software translate this spec into an Arbin schedule or Maccor procedure. The protocol file gets saved to a lab PC. Someone manually kicks off the test. Weeks (or hopefully days) later, you discover an error that a 30-second simulation would have caught.

This workflow hasn't changed in 15 years, even as everything around it has evolved.

Why This Matters More Than You Think

The protocol bottleneck creates cascading problems that impact team productivity, test reliability, and ultimately, your development timeline:

Institutional gatekeeping. Only technicians and engineers who sit closest to the cyclers know their tool's quirks and vendor software UX. This artificial constraint slows down development and test teams and creates unnecessary bottlenecks. Why should protocol creation be limited to one or two people when the entire team understands the test specification?

No validation layer. Modern software development wouldn't dream of deploying code without testing it first. Yet we routinely launch multi-week battery tests without validating the protocol logic. Simple simulation and pre-flight checks could prevent costly mistakes before they consume weeks of lab time.

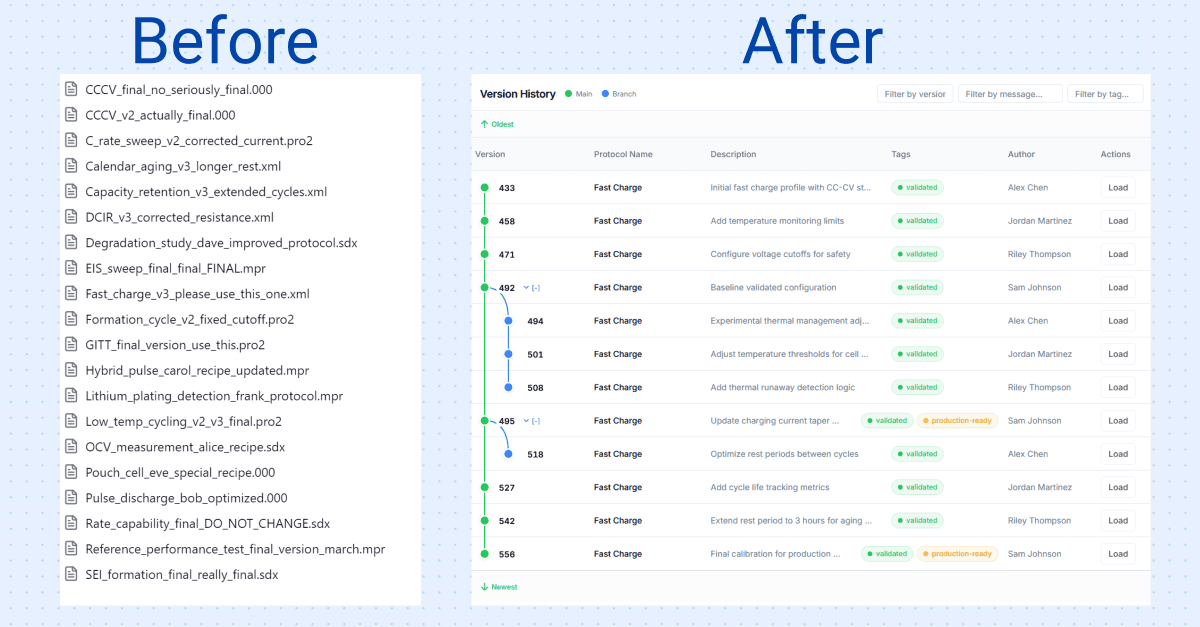

Version control chaos. Protocol files scattered across lab machines, with naming conventions like "HPPC_v3_final_ACTUAL.proc" as the only history tracking. There's no way to see what changed between versions, no ability to collaborate on protocol development, and no audit trail for potential compliance requirements.

Multi-vendor multiplication. Labs with Maccor, Arbin, and Neware cyclers often rebuild the same test multiple times. Each translation introduces opportunities for inconsistency. Each cycler requires its own expert. The same conceptual test becomes three separate maintenance burdens. Maintaining a single source of truth is the missing piece here.

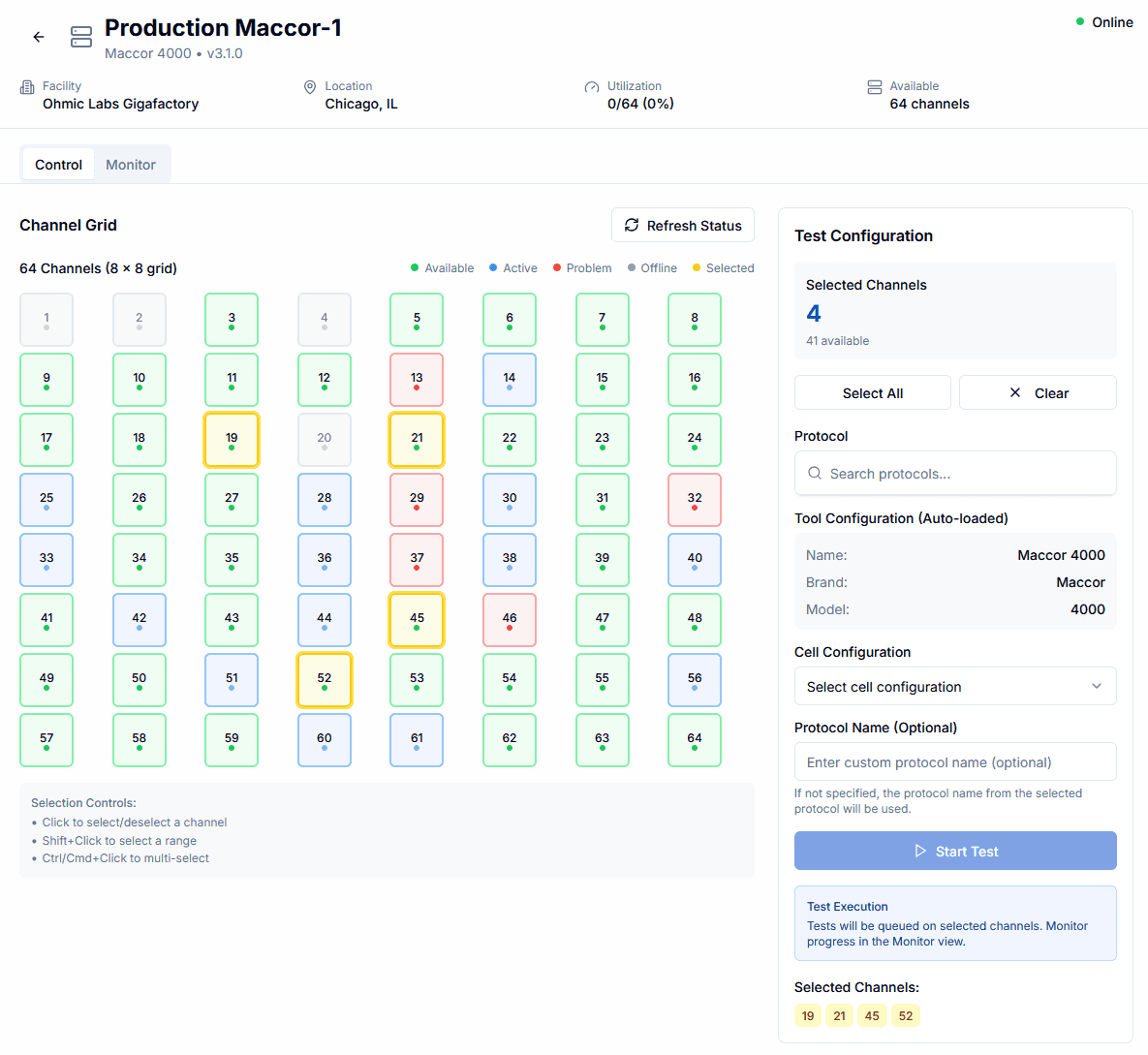

Distributed operations, disconnected workflows. Modern labs span multiple sites and cycler brands, but managing them still requires physical presence—there's no unified view of what's running or available. Fleet Manager changes this: build a protocol once, then deploy and monitor your entire testing infrastructure from your desk.

A Modern Approach to Protocol Management

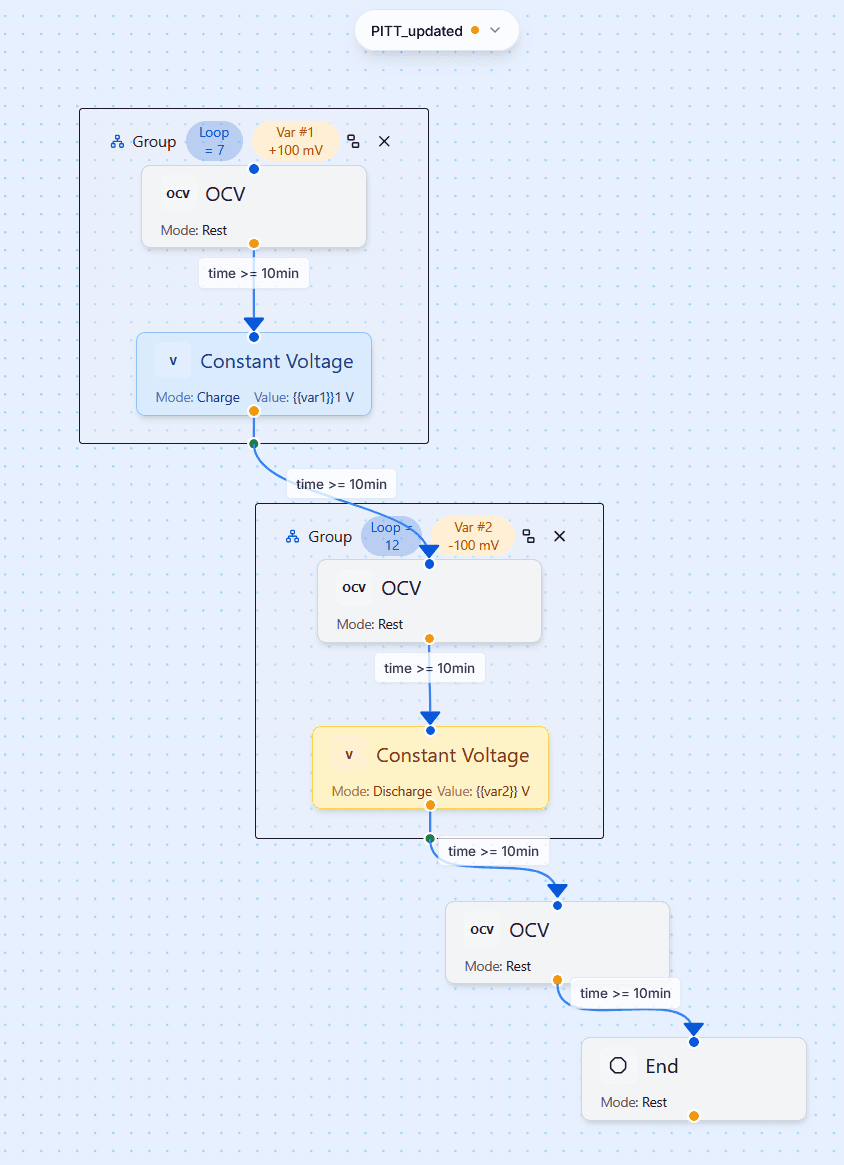

At Ohmic Labs, we've built a cloud-native platform that brings protocol management into the same era as your data analytics tools. Teams can build test protocols in a modern interface without needing cycler-specific expertise. Logical simulations can quickly validate protocol logic before tests run, catching errors in seconds instead of weeks. Versioning provides complete history tracking and enables true collaboration on protocol development. And a unified data model translates seamlessly to Maccor, Arbin, or Neware—write once, deploy anywhere (and we're working hard to extend our integration with other cyclers).

Protocol collaboration is something that has been sorely missing from the battery testing workflow. Communicating protocols whether simple or complex has generally occurred via spreadsheets, documents, and PDFs. This format doesn't allow for effective collaboration - whether working internally or externally. Our goal with the Ohmic Labs platform is to help consolidate protocol building in one place - whether it's a vendor or team member.

This isn't about adding complexity—it's about removing friction from your existing workflow. The battery industry has proven it can modernize. We've done it for data analytics, and we're seeing it happen in lab automation and protocol management.